Not only is MasterForm Australia’s leading formwork systems supplier, but we are also the inventor of the patented rapid rebate cast-in wet area setdown formwork system. We keep ourselves ahead of the curve to ensure that we design faster, safer, and simpler solutions. We supply our rapid rebate formwork products to customers across Australia, meaning we can assist in your construction project no matter where you are.

Setdowns & Rapid Rebates

Innovative Rapid Rebate and Setdown Formwork Products

Rapid Rebate Formwork

Our rapid rebate formwork is a proprietary, shop drawn and manufactured formwork system from MasterForm that is supplied on a system of legs for easy, quick, and accurate formation of setdowns in wet areas.

Features and Capabilities

- Custom made to project specifications in relation to depth and shape

- Shop drawn by MasterForm systems with leg heights to suit deck profiles

- Provides excellent adherence for membranes

- Designed by form workers for form workers

- No stripping of formwork required due to the system being fully cast in

- Improved quality and accuracy

- Installed in less than half the time of conventional formwork resulting in substantial labour savings

- It has a flat, finished edge, eliminating the need for chipped concrete edges and / or edge divots

- Complicated shapes can be easily manufactured

- Available in any depth including: 25, 30, 35, 40, 45, 50, 55, and 60mm rebate options

- Installed in less than half the time of conventional formwork resulting in substantial labour savings

- Available in radius profiles

Features and Capabilities

- Custom made to project specifications in relation to depth and shape

- Shop drawn by MasterForm systems with leg heights to suit deck profiles

- Provides excellent adherence for membranes

- Designed by form workers for form workers

- No stripping of formwork required due to the system being fully cast in

- Improved quality and accuracy

- Installed in less than half the time of conventional formwork resulting in substantial labour savings

- It has a flat, finished edge, eliminating the need for chipped concrete edges and / or edge divots

- Complicated shapes can be easily manufactured

- Available in any depth including: 25, 30, 35, 40, 45, 50, 55, and 60mm rebate options

- Installed in less than half the time of conventional formwork resulting in substantial labour savings

- Available in radius profiles

MasterForm Setdown Form

MasterForm can provide our customers with a metal setdown formwork system that speeds up the process of establishing setdowns in concrete and eliminates the need to strip any formwork.

Features and Capabilities

- Requires only a few minutes to setup and install, making it an extremely fast and time-saving process

- No more having to form up expensive or labour-intensive temporary timber formwork

- No need to strip timber after the slab has cured. Just set and forget

- Our super strut legs are custom made to suit the required slab depth and are capable of withstanding most concrete surcharge loads. They can be fixed to either ply or metal deck as required

- corners and joiners are available

- Available up to 300mm high

- Legs manufactured to custom heights

- Comes in 3m lengths

Features and Capabilities

- Requires only a few minutes to setup and install, making it an extremely fast and time-saving process

- No more having to form up expensive or labour-intensive temporary timber formwork

- No need to strip timber after the slab has cured. Just set and forget

- Our super strut legs are custom made to suit the required slab depth and are capable of withstanding most concrete surcharge loads. They can be fixed to either ply or metal deck as required

- corners and joiners are available

- Available up to 300mm high

- Legs manufactured to custom heights

- Comes in 3m lengths

Not only do MasterForm have a great range of products, but they were also prepared to come out and customise a unique solution for our needs. Professional and reliable service that’s second to none.

Murray Beljon

Director, DM Formwork

The use of a permanent cast-in system for the creation of a step or recess in a concrete slab is also protected by Australian and International Intellectual Property Patents.

How To Install Rapid Rebates

1. Set the legs

Mark out the edge of the set down onto the formwork and align the back of the leg baseplate with this edge then screw rebate legs to the formwork at 1500mm max centre’s and adjacent to corners.

1. Set the legs

Mark out the edge of the set down onto the formwork and align the back of the leg baseplate with this edge then screw rebate legs to the formwork at 1500mm max centre’s and adjacent to corners.

2. Connect the Rapid Rebate to the support leg

Screw rapid rebate frame onto the rebate leg either into the vertical or horizontal flange.

3. Concrete pour

Pour concrete ensuring to equally distribute the flow of concrete to either side of the rebate leg during the pour. The top and bottom edges of the profile will set your datum’s.

3. Concrete pour

Pour concrete ensuring to equally distribute the flow of concrete to either side of the rebate leg during the pour. The top and bottom edges of the profile will set your datum’s.

Related Setdown and Rapid Rebate Products

The use of a permanent cast-in system for the creation of a step or recess in a concrete slab is also protected by Australian and International Intellectual Property Patents.

Edge Rebate Setdown Form

- Custom made to suit modified profiles

- The perfect way to set up a water detail for concrete panels and block work on the edge of a slab

Double Rebate Setdown Form

- Custom made to suit bespoke profiles

- These are cast in, so there’s no need to strip

Setdown Support Legs

- Easily create recesses in the slab without needing any complicated formwork

- The slimline leg design can be safely cast into the slab without any risk of creating air pockets

- No need to waste valuable time assembling, measuring, or adjusting as all supporting legs come fully assembled to the height and size required

- Cast in legs can be made to suit either ply or metal decks

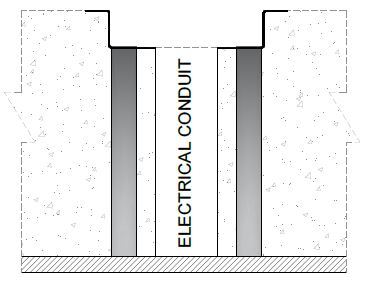

Data Boxes

- Custom made to suit project requirements

- Supplied with cast in legs at heights to suit slab depths

- No need to strip and super easy to install

Straddle Brackets

- Manufactured to suit height and rib width

- Ensures that the leg will always be the perfect height

Radius Setdown Form

- Taken directly from the CAD files to ensure accuracy

- Manufactured to custom height as required

- Supplied with key plans for quick and accurate installation

- Supplied with flat top legs set to height

- Cast-in system, so no stripping is required

Rapid rebate

- Shop drawn by Masterform to suit project requirements

- Legs set to correct height

- Cast-in system for quality control and reduced labour

FAQ

Simply send your concrete profile plans through to MasterForm for an obligation-free schedule and quote.

Yes. MasterForm can provide you with a number of warranted systems form various manufacturers that have been tried and tested on our products.

Yes. Any depth is available.

As long as the wet concrete is uniformly placed around the support legs then very little movement is usually experienced. MasterForm normally manufacture slightly oversize to allow some tolerance.

Time, quality and cost will all be improved by using the system.

Typically 5-7 days from approval of shop drawings.

Yes. MasterForm will take these radius profiles directly from the architectural DWG to ensure perfect co-ordination.

Yes. Rapid rebates usually come as single assembly and the legs are pre-set to a height for rapid installation. No stripping is required which further saves time.

Yes. As the rapid rebates are cast-in then the possibility of Edge divots that are created from stripped rebate systems is completely eradicated. The top and bottom of the profile also sets a datum for flatter and more accurate slabs.

Contact Our Team Today

If you require rapid rebate formwork products for your project, MasterForm can help. Contact MasterForm today by filling in our online contact form or alternative you can call us on (03) 9457 3811 for a quote.