HOBS (CAST-IN)

Our flagship product.

MasterForm Hobs have been on the market for over 10 years and have been specified in thousands of projects across Australia. Supplied in standard 3m lengths / cut to suit on site.

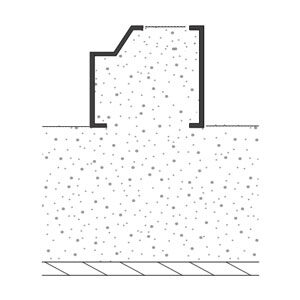

MasterForm offers a unique, revolutionary and simplified way of installing hobs by enabling them to be poured in a single monolithic process with the slab.

SAVE TIME

The secret is in our patented cast-in support leg which gets fixed directly to the deck, securing the hob in place during the slab pour.

Hobs and slabs are poured concurrently for maximum program efficiency with no more unnecessary time spent forming up and stripping formwork or extra site visits to drill and set up starter bars.

Window and façade frames can immediately be measured and ordered, speeding up the construction program.

INCREASE QUALITY

MasterForm’s cast-in hobs are more resistant to movement because they are poured with the slab, forming a true monolithic structure with no cold joints susceptible to cracking over time.

As the hobs will expand and contract uniformly with the slab they will provide a much better solution for many of the

waterproofing issues plaguing the building industry.

REDUCE COST

Our hobs can be installed in only a fraction of the time and cost of doing it conventionally freeing up valuable site resources.

Our flagship product.

MasterForm Hobs have been on the market for over 10 years and have been specified in thousands of projects across Australia. Supplied in standard 3m lengths / cut to suit on site.

Concrete truck been and gone ?

If you’ve already poured your slabs we can still save you time with our Post-Fix hobs. Just fix the hobs down onto your existing slab and keep moving. Supplied in standard 3m lengths / cut to suit on site.

Perfect for external areas with monolithic slab falls.

You can cater for all your internal/external slab steps with our Uneven Hobs. Give us the dimensions and we’ll take care of the rest. Supplied in standard 3m lengths / cut to suit on site.

Keep the Architect’s happy.

If straight lines aren’t your thing then our Radius/ Segmented Hobs are what you’ll need. Send us your CAD files and we’ll let our machines take care of the rest.Supplied in 2.4m max. lengths.

When you need that off-form finish.

If you need a rendered finish on the external face of your hobs, try out our Removeable Skin Hob (Single) availabe in single removeable skin configurations. Supplied in standard 3m lengths / cut to suit on site.

When you need that off-form finish again..

If you have a critical hob pour that needs both faces left off-form, try out our Removeable Skin Hob (Dual) availabe in dual removeable skin configurations. Supplied in standard 3m lengths / cut to suit on site.

All of our hobs can be supplied with Ends to suit the individual hob sizes and can be screw fixed in place on site after establishing your hob alignments. Supplied as individual items.

All of our hobs can be suppplied with Corners to connect horizontal transitions in the hob alignment. One piece for the outside, one piece for the inside. Supplied as individual items.

Use our Joiners to connect longitudinal runs of hobs together. One joiner per hob skin / 2 joiners per join. Supplied as individual items.

Establish all of your door & window rebates quickly

Our Double Rebates are designed to accomdate any width or depth of subsill required and allow you to pour these rebates monolithically with the slab. Supplied in standard 3m lengths / cut to suit on site.

Same idea as our standard Double Rebates but these ones can accommodate your radius or segmented alignments Supplied in maximum 2.4m lengths.

These hobs come with a top notch for matching up with your precast panels. Send us your precast drawings and we’ll accomdate any size of notch needed.

Complies with AS 4654.2.

No one wants water ingress issues so when the detailing needs to be extra critical use our Waterstop Compliant Hob and take the worry out of things.

The faster, easier and cheaper solution to your hobformwork needs!

4 Easy Steps To Install Your MasterForm Hobs

Step

01

Step

01

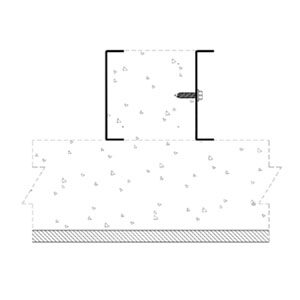

Mark the center line off the hob onto the formwork and align with the ‘V’ in the center of the hob leg base plate. screw fix legs onto either the ply or metal deck, ensuring all legs are rotated in the same direction. Legs should be spaced approx 1.2 – 1.5 metres apart, with a leg adjacent to each corner.

In situations where the bottom of the slab will be exposed we suggest fixing the legs onto our custom 25mm bar chairs. This will allow the concrete to flow under the plate, hiding it from view.

Step

02

Step

02

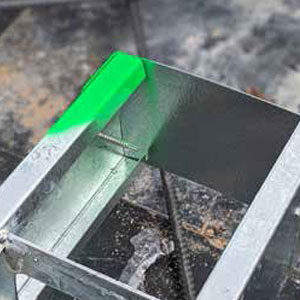

Position hob over the legs and push down using hands or base of foot until you hear the secure clipping sound of the Klipmaster leg and hob interlocking.

We recommend using tie wire to further brace and secure the hobs if needed for tall legs and very long straight runs.

Step

03

Step

03

Create corners, join hobs and install end caps quickly and easily by using one of our MasterForm hob custom ancillary products.

Step

04

Step

04

fill the slab area directly below the hob first and then fill the hob taking care to ensure that the concrete is still wet to avoid cold jointing.

IMPORTANT: Equally distribute the flow of concrete to either side of the hob leg during the pour, ensuring an even pressure is maintained along its length to avoid the hob from twisting.

Request a QuoteMasterForm range of products are licensed and distributed by MasterForm Systems Pty Ltd

405 Francis St Brooklyn, VIC 3012

Phone: 1300 000 405

Email: info@masterform.com.au

MasterForm cast-in hobs are provided with hob legs pre-set to the required slab depths. Our hobs sit on top of the proprietary Klipmaster hob legs, when pressure is applied the hob simply and securely clips into place. Any reinforcement details are to be designed by the project engineer.

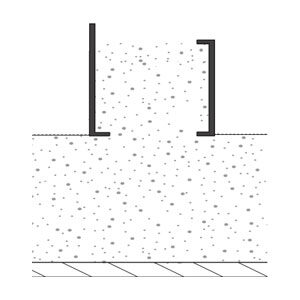

MasterForm post-fix hobs are quick and easy to install and are a fully cast-in system therefore saving time on stripping.

MasterForm post fix hobs are installed with M8 x 100mm concrete screws at each hob spacer location (approx. 500mm crs.). Any reinforcement requirements are to be designed by the Project Engineer.

MasterForm supply straddle brackets that adapt to the profile of the metal formwork system that are using. Simply confirm your profile with MasterForm.

As long as the wet concrete is uniformly placed around the support legs then very little movement is usually experienced. Legs taller than 300mm usually require some stabilization with tie wire. We also suggest some simple tie wire cross supports on the hob lengths as the guys on site feel necessary.

MasterForm hobs are 3m long.

Yes. MasterForm will extract the profile directly from the architectural DWG background and supply you with a keyplan for quick and accurate installation.

MasterForm will provide you with 25mm plastic bar chairs to sit beneath the support legs to ensure a class 2 soffit.

MasterForm hobs are supplied with corners, joiners and end caps for a quick and tidy finish.

Simply send through your concrete profile plans and structural GA plans and masterform can schedule your project for you.

Yes. All MasterForm hobs are manufactured with G275 Galvanized steel. MasterForm can provide you with warranted systems from a number of suppliers recommended for use on our hobs upon request. Nothing more onerous than off-form hobs.

Typically 5-7 days from shop drawing approval however shorter time frames are possible.

All MasterForm hobs are manufactured in Melbourne and shipped anywhere in Australia on an express service.

MasterForm is Australia’s leading hob manufacturer. Our hobs have been used on projects all over the country including, Westside place Melbourne, Aurora in Melbourne, Capital Grand in Melbourne, The ribbon in Sydney, ParkOne in Sydney.

MasterForm Hobs create an accurate and consistent hob profile that is easy for filling. The pre-fabricated hob eliminates the warping and twisting of timber formed hob. MasterForm Hobs also eliminates the need for coming back and stripping the timber away from the hob once the concrete is cured, saving considerable amounts of time.

Using the range of MasterForm products has had a very positive impact on our cycle times. Their team is always available with advice and recommendations for tricky and intricate formwork requirements.

Structures Manager, Hickory Group

The use of a permanent cast-in system for the creation of a monolithic hob/bund in the concrete slab is protected by Australian and International Intellectual Property Patents.

If you require premium hobs for your project, contact MasterForm today by either filling in our online contact form or calling us on 1300 000 405 for a quote.

Get A Quote