What We DO

Helping Australian Clients for Over 30 Years

MasterForm takes pride in having built long-term partnerships with our clients, some of whom we have been in collaboration with since the business first started 30 years ago.

We have a proven track record in successfully manufacturing and supplying our comprehensive range of metal form work products, as well as tailoring custom solutions for projects to reduce costs, improve quality, and accelerate floor cycles. We have helped customers in Melbourne, Sydney, Adelaide, Brisbane, and elsewhere in Australia with our vast array of innovative, patented form work products.

Masterform Products

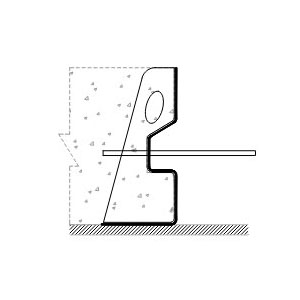

Our flagship product.

MasterForm Hobs have been on the market for over 10 years and have been specified in thousands of projects across Australia.

Supplied in standard 3m lengths / cut to suit on site

Concrete truck been and gone ?

If you’ve already poured your slabs we can still save you time with our Post-Fix hobs. Just fix the hobs down onto your existing slab and keep moving.

Supplied in standard 3m lengths / cut to suit on site.

Perfect for external areas with monolithic slab falls.

You can cater for all your internal/external slab steps with our Uneven Hobs. Give us the dimensions and we’ll take care of the rest.

Supplied in standard 3m lengths / cut to suit on site.

Keep the Architect’s happy.

If straight lines aren’t your thing then our Radius/Segmented Hobs are what you’ll need. Send us your CAD files and we’ll let our machines take care of the rest.

Supplied in 2.4m max. lengths.

When you need that off-form finish.

If you need a rendered finish on the external face of your hobs, try out our Removeable Skin Hob availabe in single or double removeable skin configurations.

Supplied in standard 3m lengths / cut to suit on site.

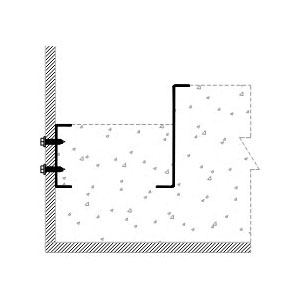

Establish all of your door & window rebates quickly

Our Double Rebates are designed to accomdate any width or depth of subsill required and allow you to pour these rebates monolithically with the slab.

Supplied in standard 3m lengths / cut to suit on site.

Same idea as our standard Double Rebates but these ones can accommodate your radius or segmented alignments

Supplied in maximum 2.4m lengths.

Our Rapid Rebates are custom made to project specifications in relation to wet area setdown depth and horizontal geometry.

Available in any depth between 15mm-100mm.

Our custom manufactured penetration forms come with rated mesh and are designed to withstand imposed temporary construction loads and to mitigate the risk of live edges as well as the time and cost associated with establishing temporary fall protection.

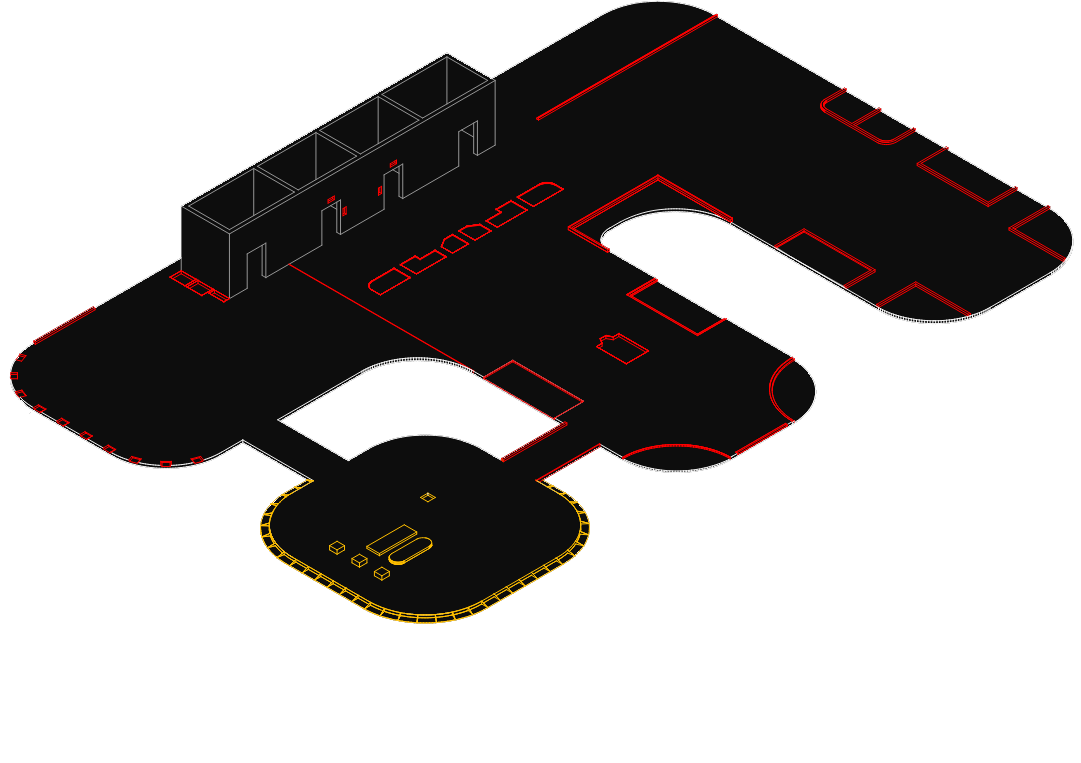

Our custom reusuable steel edge form system is designed in-house and allow sites to quickly and accurately establish curved slab edges.

Special key joint between segments allows for accurate installation especially for curved formwork and void formers and PT slots can be incorporated into the edge form to suit project specifications if required.

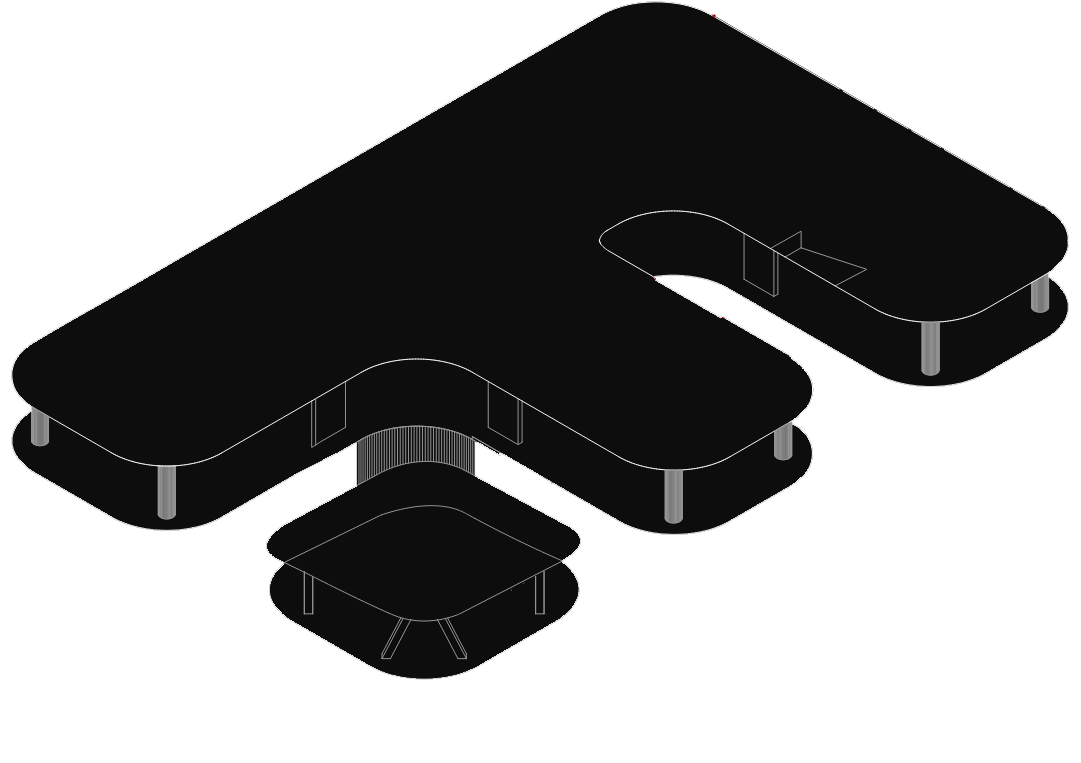

Our metal plinths are fabricated to suit your project requirements and can be supplied with supporting legs to allow for a monolithic pour with your slab, or they can be post fixed to an existing slab in a retrofit scenario.

No stripping required.

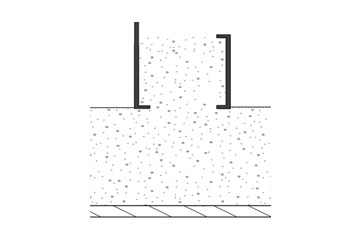

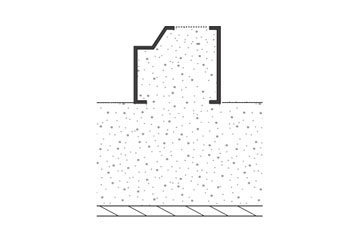

A cast-in metal set down formwork system which speeds up the process of establishing set downs in concrete and eliminates the need to strip any formwork.

Requiring only a few minutes to setup, this system is extremely cost effective and fast to install. Our cast-in supporting legs are custom made to suit the required slab depth.

No need to strip, just set and forget.

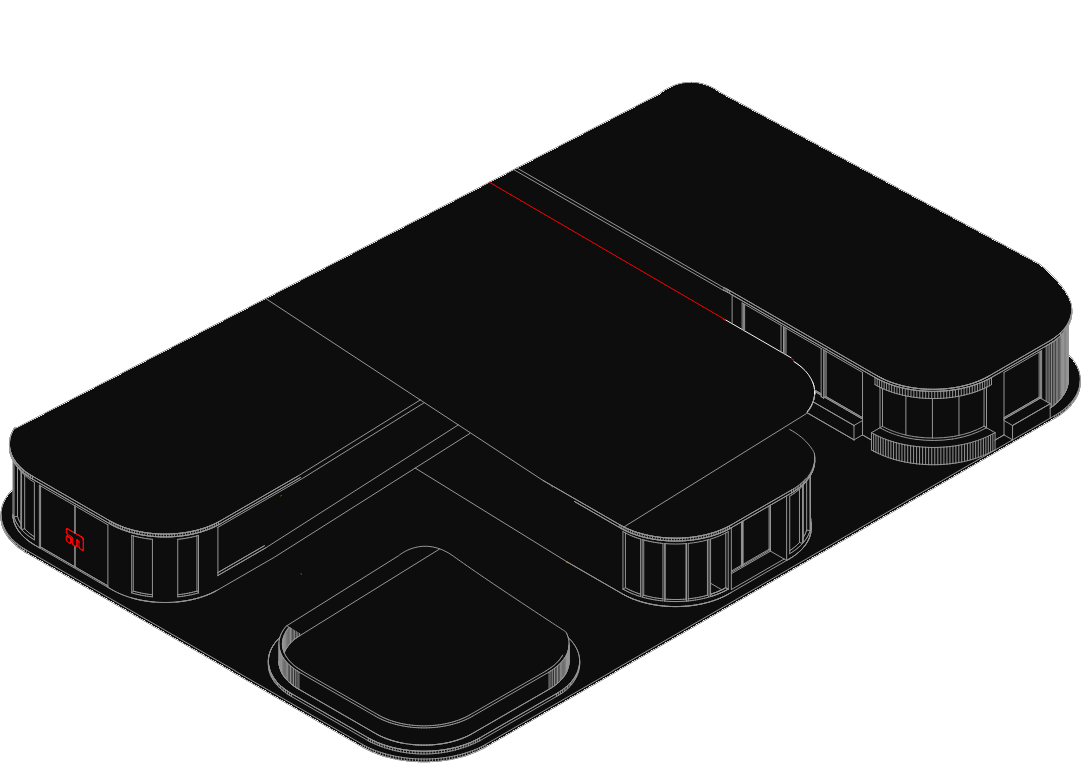

Our Cast-in EdgeForm is the quickest way to setup a suspended slab stop end.

Custom made to suit project requirements with no need to strip.

Perfect for forming up against existing walls or inaccessible areas.

Available with or without gussets depending on depth.

Our Cast-in EdgeForm with Hob is perfect for slab edges the quickest way to setup a suspended slab stop end and can be supplied with integral hob if project requirements dictate.

Can include ferrules for balustrade/screen fixing.

Perfect for slab edges being covered by cladding or facades.

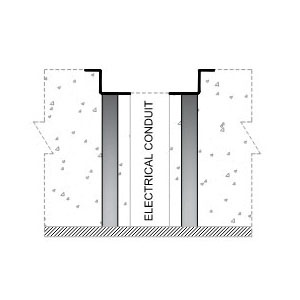

Cast-in metal lift button boxes to suit project requirements. Provision for electrical conduits accommodated. More accurate and cost effective than forming with foam or timber.

All of our pocket formers are shop drawn to cater for your specific project requirements and are designed to be cost effective.

A reusable steel form placed around your concrete pump tower. Our low profile design minimises the infill slab area and allows for easy stripping around the concrete pump tower.

Supplied to suit your project requirements.

A lightweight, cast-in Construction Joint profile used along your pour breaks and fixed directly to the deck. A range of key dimensions can be accommodated. Supplied in standard lengths / cut to suit on site.

A cast-in product for creating edge rebates. just set and forget.

Available in a variety of configurations to suit project requirements.

No need to dread when you see data boxes on the plans any longer. These lightweight, fabricated boxes are specifically designed to create recessed pockets in the top surface of your slab.

Leg heights and cast-in box dimensions are tailored to suit product dimensions.

Complies with AS 4654.2.

No one wants water ingress issues so when the detailing needs to be extra critical use our Waterstop Compliant Hob and take the worry out of things.

A cast-in radius metal set down formwork system designed to speed up the process of forming radius set downs whilst providing absolute accuracy that is true to the architects documentation.

These hobs come with a top notch for matching up with your precast panels.

Send us your precast drawings and we’ll accomdate any size of notch needed.

The only hob you can trust

The Hassle free set-down system

Because safety comes first

Perfect all round

On Site with MasterForm

It all starts in setup.

The Aptus system relies on these reusable metal shutters, used as stop ends for the tops and bottoms of each precast element. They’re not just holding shape; they’re locating the Aptus bars with millimetre accuracy so every coupler lines up once the elements are stacked on site.

It’s a simple, tough bit of kit that makes the whole system work from start to finish.

#MasterForm #AptusSystem #PrecastConcrete #Formwork #ConcreteConstruction #StructuralEngineering #BuildSmarter #ConstructionLife #CivilEngineering #ConstructionInnovation

We don’t talk about our Shutter Templates nearly enough… but they’re a big part of how projects like this come together.

Here’s a look at the before and after 👉 Custom profiled steel plates give you the accuracy to form curved upstands, walls, or deeper slab steps. From there, it’s simply a matter of building up your shutter on-site with timber and ply.

#ShutterTemplates #MasterForm #ConstructionInnovation #FormworkSolutions #ConcreteDesign #BuildingSmarter #CurvedConcrete #OnSiteProgress #MelbourneConstruction

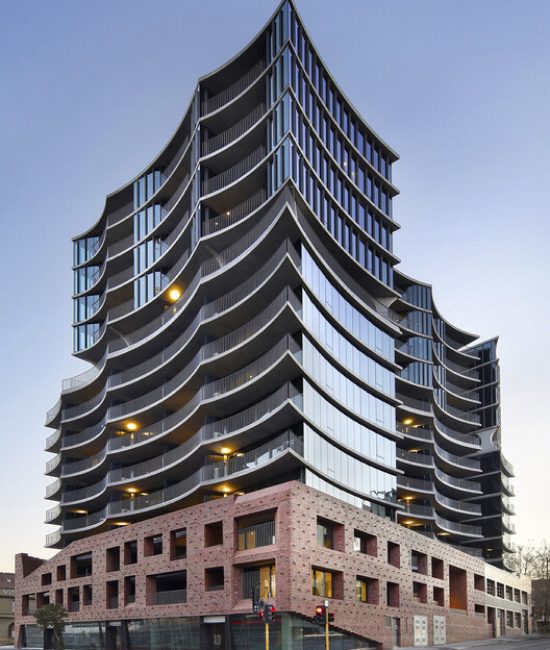

Loving the way The Raleigh in Windsor has come together, those curves are something else. Hats off to the team on-site 👷♂️👏 but honestly, we couldn’t achieve this level of precision and smoothness without Ezy EdgeForm.

#EzyEdgeForm #MasterForm #ConstructionInnovation #BuildingSmarter #FormworkSolutions #ConcreteDesign #MelbourneConstruction #OnSiteProgress #FormworkDesign #ArchitectureInConcrete @goldfields_group

Ezy EdgeForm is hard at work on the Meriton ICONICA Tower in Surfers Paradise, delivering precision, speed, and perfectly curved slab edges on one of Queensland’s most iconic projects.

This custom formwork system has become part of the build, proving its strength and versatility as the tower takes shape on the Gold Coast skyline. 🚧

#EzyEdgeForm #MasterForm #ConstructionInnovation #GoldCoastProjects #BuildingSmarter #MeritonGroup #FormworkSolutions #QLDConstruction #OnSiteProgress #FormworkDesign #ConcreteConstruction @meriton_group

Some curves just can’t be done with timber.

This is Ezy EdgeForm, our in-house steel edge board system that locks in smooth, repeatable curves with speed and accuracy.

It’s all held in place with a keyed joint system, and for tighter radii, we use internal shutter templates like the 450mm one on this deck, locking in the curve for a clean result.

Want to save days on-site and finish with a cleaner edge? This is how it’s done.

🔗 link in bio

#MasterForm #EzyEdgeForm #CurvedSlabEdge #FormworkGear #ConcreteDetail #AussieBuilders #EdgeFormSystem

On site. On the phone. On the case.

Sometimes the gear isn’t the only thing holding the job together.

Shoutout to everyone behind the scenes making it happen, early starts, late calls, and a bit of chaos in between.

#MasterForm #SiteLife #ConstructionCrew #MakingItHappen #BehindTheBuild #AussieBuilders #FormworkThatWorks #TradieLife #WorksiteViews

We talk a lot about getting the pour right, but that only happens when your formwork is sorted from the start.

MasterForm hobs have been refined over years of trial, testing and tough site conditions, and it shows.

They’re consistent. They’re fast. And they do exactly what they’re meant to.

If you`re still patching, reworking or resetting, maybe it’s time to see how we do things.

Get in touch. We’ll show you what good looks like.

🔗 link in bio

#MasterForm #CastInHobs #FormworkGear #ConcreteWork #NoRework #AussieConstruction

Still messing with patchy hobs and rework after the pour?

That’s time you don’t get back.

MasterForm cast-in hobs are fixed in position before the pour, so what you set is what you get.

✅ No shifting

✅ No stripping

✅ No realignment

Just a clean, monolithic pour - first go.

🔗 link in bio

Let’s make rework a thing of the past.

#MasterForm #CastInHobs #ConcreteFirstTime #FormworkThatWorks #SiteReady

Are you still propping hobs with blocks and hope?

Still cutting timber and patching it later?

There’s a better way.

Cast-in hobs stay put during the pour, no shifting, no stripping, no surprises.

If you’re not already using them… maybe it’s time to ask why.

🔗 link in bio

Want a closer look? Get in touch - we’ll show you how it works.

#MasterForm #CastInHobs #SiteReady #NoRework #ConcreteDoneRight #AussieBuilders

Faster doesn’t mean cutting corners.

MasterForm hobs install quicker than traditional setups - and they deliver a cleaner finish too.

The system’s designed to pour once and walk away. No stripping. No patching. No second pass.

“We eliminate cold joints, which in turn eliminates cracking and water issues.”

Less rework. Better finishes. No drama.

🔗 link in bio

#MasterForm #FormworkThatWorks #NoRework #ConcreteDoneRight #AussieBuilders

Fast, solid, and locked in.

Our patented Klip-Lok cast-in support leg holds the hob in position during the pour - no shifting, no mess.

It’s faster to install and saves hours in setup and labour.

“This system installs in a fraction of the time compared to traditional hobs - and it stays where you put it.”

More speed. Less rework. Better outcomes.

🔗 link in bio

#MasterForm #KlipLokSystem #CastInHobs #FormworkGear #QuickSetup #SmartSiteSolutions

It’s not just what you pour - it’s how you prep.

The real difference with MasterForm hobs? The way they’re fixed into position.

Every frame locks down tight with cast-in legs and smart detailing, so what you pour is what you keep.

No drift. No shifting. No realignment.

It means faster prep, smoother pours, and hobs that are locked in and ready to go the first time.

🔗 link in bio

#MasterForm #CastInHobs #FormworkThatWorks #ConcreteGear #NoColdJoints #OnTheTools #AussieBuilders

Before & after with MasterForm Safety Peno 🔒

Set it once. Pour with confidence.

✔ No extra labour

✔ No trip hazards

✔ No stress on-site

Because safety should be part of the plan - not an afterthought.

#SafetyFirst #MasterForm #SiteSafety #FormworkInnovation #ConcreteConstruction #CastInFormwork #SmartFormwork

Safety Penos - Simple but serious

Live edges and exposed penetrations slow things down - and put people at risk. MasterForm Safety Penos are designed to protect crews while keeping work moving.

They’re fast to install, pre-capped, and stay rated until you`re ready to cut in. No makeshift covers. No rework. Just clean, safe, set-and-forget protection.

#MasterForm #SafetyPenos #SiteSafety #FormworkThatWorks #BuildingSmarter #ConcreteSolutions #ConstructionGear #AussieBuilders #NoLiveEdges

The Raleigh, Windsor - Looking sharp.

Another top-tier build from Goldfields Group, and we’re proud to be on board supplying the gear that keeps things moving.

From crisp slab edges to seamless setdowns, our systems help crews work faster, cleaner and safer - all while delivering a top finish.

This is the kind of site where formwork that actually works makes all the difference.

🔗 link in bio

#MasterForm #GoldfieldsGroup #TheRaleighWindsor #MelbourneConstruction #ConcreteGear #SiteReady #FormworkThatWorks #BuildingSmarter #AussieBuilders @goldfields_group

It’s All About the Legs

They might not be the star of the show - but without the right legs, nothing stands right.

We offer a full range of MasterForm legs to suit every formwork setup:

• Fixed

• Adjustable

• Cast-in

• Clip-on

• Radius options for curves

Each one is designed for stability, precision, and speed on-site - whether it’s for hobs, rebates, plinths or custom frames.

💡 It’s the small details that make a big difference.

🔗 Learn more: link in bio

#MasterForm #OnTheTools #ConstructionGear #AussieBuilders #PrecisionFormwork #SiteReady #MadeForBuilders #SteelFabrication #FormworkSetup

Ezy EdgeForm in action - holding the line where it counts.

This close-up shows exactly why factory-fitted brackets make all the difference.

✔️ Consistent spacing

✔️ Secure edge hold during pour

✔️ No warping, no blowouts

✔️ Perfect prep for a clean strip line

If you’re still cutting timber and adjusting by eye, you’re wasting time and risking rework.

Ezy EdgeForm gives you the edge - literally.

📩 Want more info or specs?

👉 Visit: link in bio

#ezyedgeform #formworksolutions #masterform #siteprep #concreteedge #brackettech #formworkdonebetter

End of an Era - Start of a Smarter One

This old press from the 80s helped kick off the MasterForm revolution - and it’s been with us every step of the way.

Now it’s time to level up. We’ve just welcomed in a new press, roller, and laser, all tied together with a smarter, more automated system - including elements of AI integration.

More precision. Less waste. Faster turnaround.

Here’s to the future of fabrication - and to the crew who’ve built every step with us.

#MasterForm #AutomationInManufacturing #FabricationUpgrade #AIinConstruction #SmartFactory #MadeForBuilders #BuildingSmarter #LegacyToFuture #FormworkInnovation

What Is Ezy EdgeForm - and Why Are More Sites Choosing It?

A quick behind-the-scenes look at how Ezy EdgeForm is set up and used on-site - from install to pour.

Concrete edges are traditionally time-consuming to prep and form. But with Ezy EdgeForm, you get a reusable, precise, and faster system designed to deliver cleaner results - every time.

✔️ Fast setup using steel brackets

✔️ Perfect curved or straight formwork

✔️ Durable enough to reuse again and again

✔️ Cleaner finish on exposed concrete edges

✔️ Lightweight, stackable, and made for tough sites

Whether you’re forming up ramps, podiums, footpaths or slabs - Ezy EdgeForm gives you more control, and less waste.

Swipe through the photos to see:

1. Ezy EdgeForm brackets in place, ready for mesh

2. Mesh and formwork fully prepped for concrete

3. Concrete being poured and levelled across the edge

4. Clean, smooth finish with a sharp strip line

Got questions or want to spec Ezy EdgeForm for your site?

Shoot us a message or hit the link in bio to learn more.

#formworksolutions #concreteformwork #ezyedgeform #constructionlife #siteprep #civilconstruction #formworkdesign #concretelife #tradietools #masterform #australianmade #pourday #buildingbetter

About MasterForm

Smart, Innovative

Hob Formwork Solutions

MasterForm is Australia’s leading supplier of cast-in and reusable metal Formwork solutions to the construction industry. We have been trusted for more than 30 years to offer fast, competitively priced systems that offer smart, innovative formwork solutions that deliver a quality build every time.

With our clear industry understanding, vast catalogue of standard products, custom solutions and personal service, we are committed to delivering the most innovative metal formwork systems to the construction industry. And It’s all done with prompt, personal service from friendly staff and guaranteed delivery times.

What Customers say about us

Happy Customers

Contact us Today

Let’s Discuss

-

405 Francis Street, Brooklyn VIC 3012

-

Monday to Friday 8:00am – 5:30pm

-

Call us 1300 000 405